rub rub rub

Good. I still had fun.

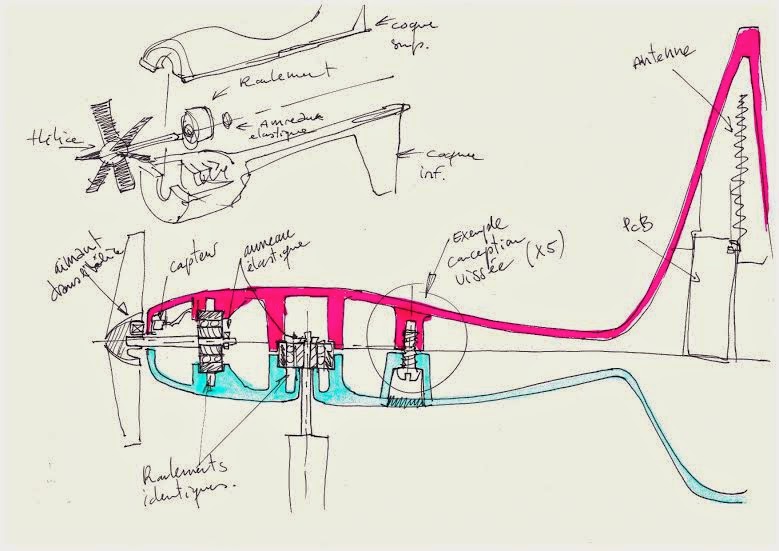

There is even a gentleman who helps me, and who made me a nice drawing:

We see our Pioupiou, its propeller, and ball bearings.

(You can also see other things, like too much leverage between the bearing and the propeller. But since I can't draw so well, I'm keeping this image there.)

Brief. There is in particular the pivot of the propeller. This is THE critical point of our Pioupiou. It will have to do tens of billions of turns. It must therefore be sufficiently robust, including in aggressive environments. (sea air…)

But at the same time, our propeller must be able to turn at the slightest breath. We want to be able to measure wind speeds of less than 5 km/h. It is therefore necessary to have a robust bearing, but which does not interfere with the rotation.

Mission 0 friction

Brief. I played a new game. It's called the " tribology ».

« Tribe- » as from the ancient Greek which means « scrub », and « -logie » like all the stuff we study at school.

We had to find a bearing that did not rub too much. There, two solutions: do math, or do less math. And since I didn't really know how to do the math, I chose the experimental method.

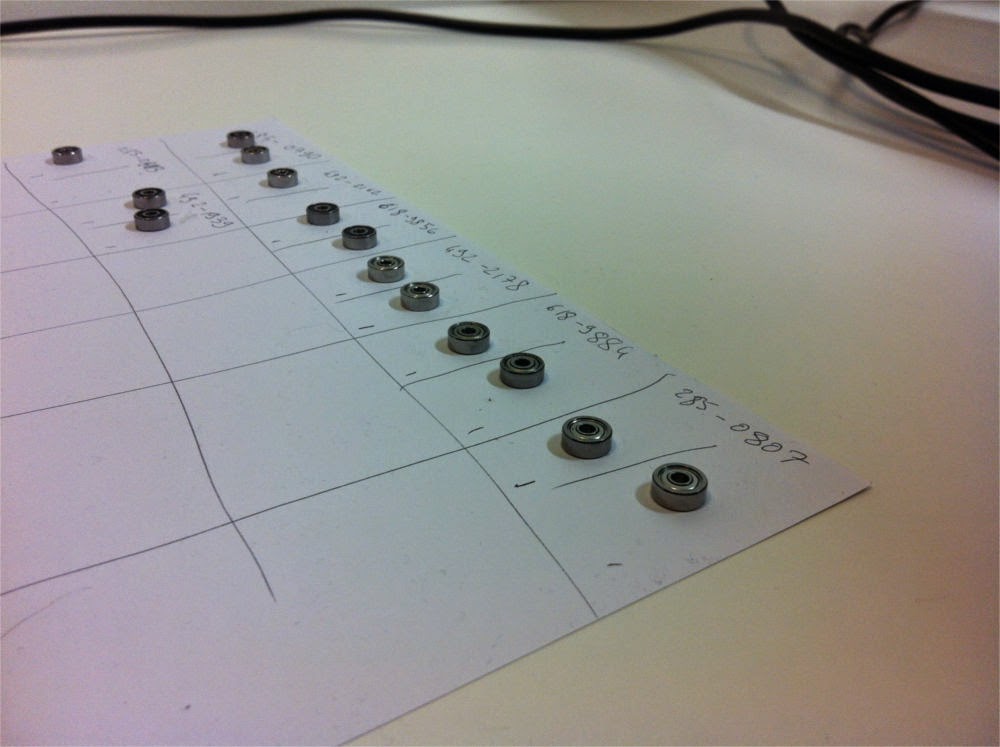

Fortunately, last week, I had exploded the ceiling of my credit card. Among the multitude of things I had bought, there was a small stock of bearings:

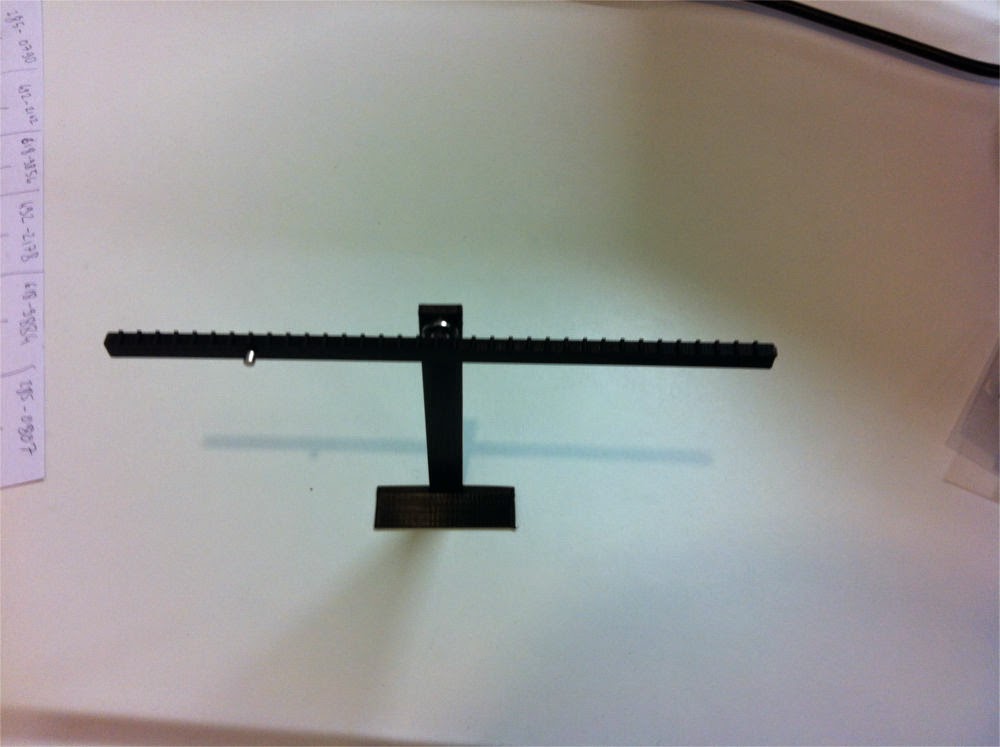

So to study them, I started by playing with the 3D printer:

To make two funny objects:

The thing on the right is a support. I fit the bearing to test.

The thing on the left is a sort of graduated ruler, which also fits into the bearing.

In short, it's a kind of balance. Here is the result:

After a few strokes with the cutters to adjust the balance, the bar holds exactly horizontal.

Then the game is simple:

We put (very small) magnets, and we move them to gradually increase the lever arm. When it rocks, it means that the weight exerted by the magnet is greater than the friction of the bearing. By multiplying the mass of the magnet by the distance, we obtain the friction torque of the bearing.

It is an approximate measurement, but which allows to have orders of magnitude for the different types of bearings. For example, my bearings " nus » had a friction of less than 0,000001 Nm While a bad sealed bearing had a friction of 0,0005 Nm It's not much, but it's still 500 times more!

Everything-proof

The bearings " sealed are good, but they are expensive in friction. This is because there is a rubber disc that presses on both sides.

We can therefore have a more reactive anemo, by putting a bearing that is a little less tight.

|

| Left: waterproof. Right: a little less watertight. |

But suddenly, it is more necessary to protect it against dust and water. But we can probably work it out. For example with a kind of "gutter" that guards the entrance:

It's time to eat. I will stop there for this week. Otherwise there will be no more raclette. And since we've just found an apartment at La Terrasse, it's not the right time to divorce.

See you soon !

10 thoughts on “ rub rub rub »

Hello Nicolas,

I draw your attention to the gutter (not that of the apartment) the water risks sliding along the profile and simply entering by depression. if the bearing is not sealed, it may soak in the long run...

I say that, but I don't know anything about it, just to complain a bit

Aie

Good evening

I don't know anything about it either (but I admire your project) but I risk these suggestions for a less sealed bearing:

- can't we shift the bearing a little while maintaining a reasonable lever arm?

- any water ingress could be evacuated through perforations in the lower part of the hull (flow and evaporation)?

This comment has been deleted by a blog administrator.

http://www.roulement-ceramique.fr/les-avantages,fr,8,7.cfm

Bearings are good when there are lateral loads, you can also look at roller bushings, self-lubricated bearings. Pay attention to the alignment of the shaft, if you put 2 bearings it is almost impossible to align so as not to put your shaft on the bias and therefore create friction. The important thing to measure weak winds, it is necessary above all that the rotating assembly has the minimum of inertia, therefore the lightest possible. Your tree also needs to be as thin as possible. If you were you, I wouldn't try to recreate a rotating part, it's excessively complicated to obtain a good result.

Good luck.

Spotty

You can also rotate your propeller around a fixed axis, it seems more relevant for the management of wear, friction, …. Quickly done on the grill…

Sea air (humidity and not wind+sand+salt) can only be avoided if you are in a 100% waterproof box. Isn't it better to have unsealed 100% stainless steel bearings than sealed steel bearings?

For the Kite/Wind the reliability of the Pioupiou is more important than the precision on the wind <5km/h or than an uncertainty of a few km/h on the measurements (because of friction). This may not be the case for paragliding.

One solution would be to have a more precise, less expensive PiouPiou (with a non-sealed bearing) and to facilitate the change of the bearing with a sealed and stainless steel bearing. It would therefore be necessary to take a brand of bearing which has the two models with the same dimensions and provide the references of the compatible bearings!

And for the propeller magnet you have to think about balancing with an equivalent mass symmetrical with respect to the axis otherwise it won't go round for long 😉

Hi nico

Have you studied the option of the bearing in the propeller? Admittedly, this makes a bigger hub, but the bearing will always be protected. The axle can be sealed: no more water entering the beacon. For assembly, an adjustment for slightly force-fitting could suffice knowing that disassembly is rare. Moreover, the wind is pushing in the right direction. Finally, this simplifies the molding of the bearing support.

Pascal

Hi Nicolas,

I advise you to take a look at the polymer plain bearings. I use them in my work and they replace bearings perfectly in certain applications. The temperature range of use is very wide, the resistance to spray is very good and there are certain materials which have a very good coef. of friction.

I advise you to go see them, they can send free samples (that's good for your card!)

http://www.igus.fr/wpck/5182/iglidurProductfinder

A+