Fly to work

After moving last week. It was Pioupiou's turn.

Here is his new home. With plenty of room to tinker:

I hope Mom won't be too disappointed that there are no more crafts in her kitchen.

In any case, there is another one that will be sad. She will no longer be able to post photos of “ my boyfriend and his brothel darling " on Facebook.

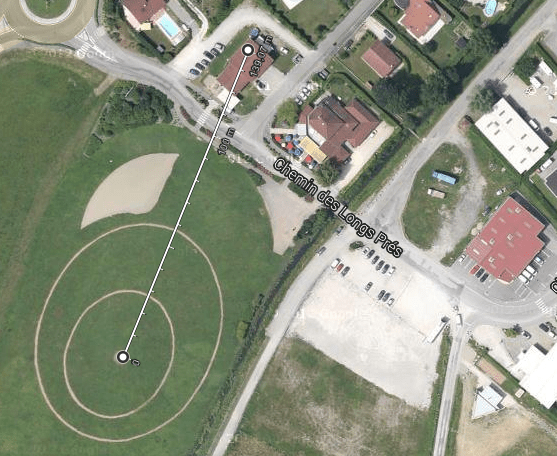

The number one criterion for the new Pioupiou's headquarters was to be able to go to work by paraglider.

Mission accomplished ! 139m from the landing of the world's most famous paragliding spot, you can hardly do better:

Perfect for taking the RER in the morning. The proof in pictures:

(and to think that a year ago, I almost managed to work two whole months in Paris…)

A little serious

So after playing well, we had to get to work.

I sent the t-shirts promised during the campaign KissKissBankBank. Casually it was a whole logistics.

Especially since La Poste asks for a K-Bis to be able to spend more than 75 € on its site “ professionals » !!! So I went through the site individuals » which only asks for a credit card number − normal. No but seriously, what are they smoking at La Poste?!

Brief. Next week, I hope we'll have lots of photos of the new followers of the Pioupiou sect, with their beautiful t-shirts.

How do we do ?

I always have this question of the propeller shaft that bothers me: how to make a durable, inexpensive connection that does not rub?

I came up with 3 solutions. Tell me what you think :

Bearings

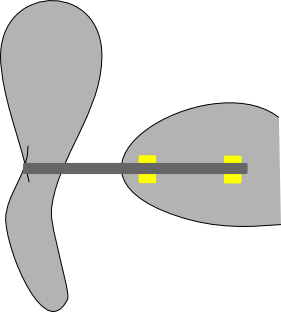

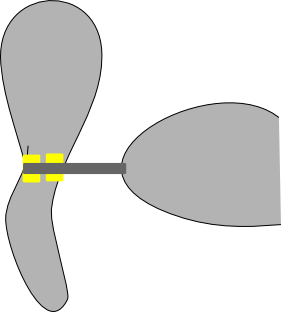

Two small bearings in the body of Pioupiou. Side by side for easy alignment.

I can't take sealed bearings (rubber flange), because it rubs too much. As a result, we are moving towards semi-sealed bearings, with a metal flange.

The housing will be studied to avoid as much as possible the penetration of water and dust into the housing. Also, the bearings will be made of stainless steel to limit corrosion. But will that be enough?

I haven't found affordable ceramic bearings in these sizes. (inner diameter: 3mm). If you have any, I'm a taker.

Polymer bearings

Another solution is to use polymer bearings self-lubricated ».

On paper, it's advantageous: no need for grease, no risk of corrosion, no fear of dust.

On the other hand, it rubs a little more. As a result, the anemo has more difficulty starting with so little wind. Then it's a question of compromise. You cannot have robustness, price and high sensitivity at the same time. Is it good if the anemo is more robust but only starts from 10km/h of wind?

You also need to study the mechanics a bit more. (bores and axis of better quality than for the bearing).

Bearings in the propeller

You can also put the polymer bearings directly in the propeller. So we reduce the lever arm, so less friction and wear, so more sensitivity? And also absence of mechanics inside Pioupiou, therefore better sealing and easy replacement.

This solution pleases me. I need to study it in detail.

These bearings are used in bicycle derailleurs. So it shouldn't be a problem if they're not safe in the case?

In search of the right propeller

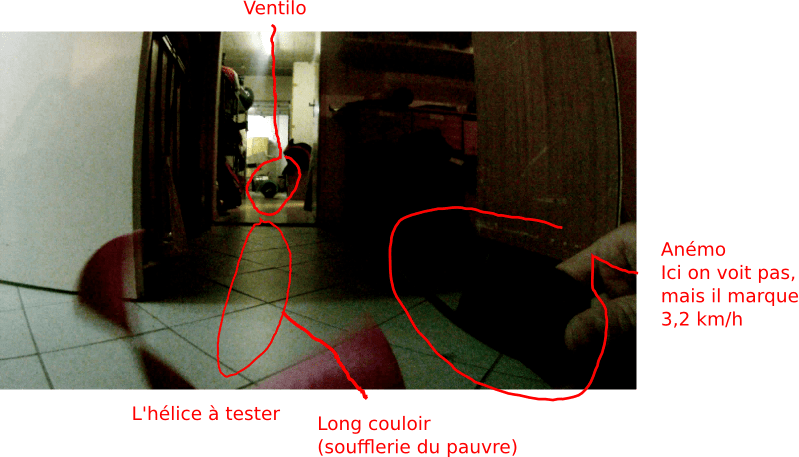

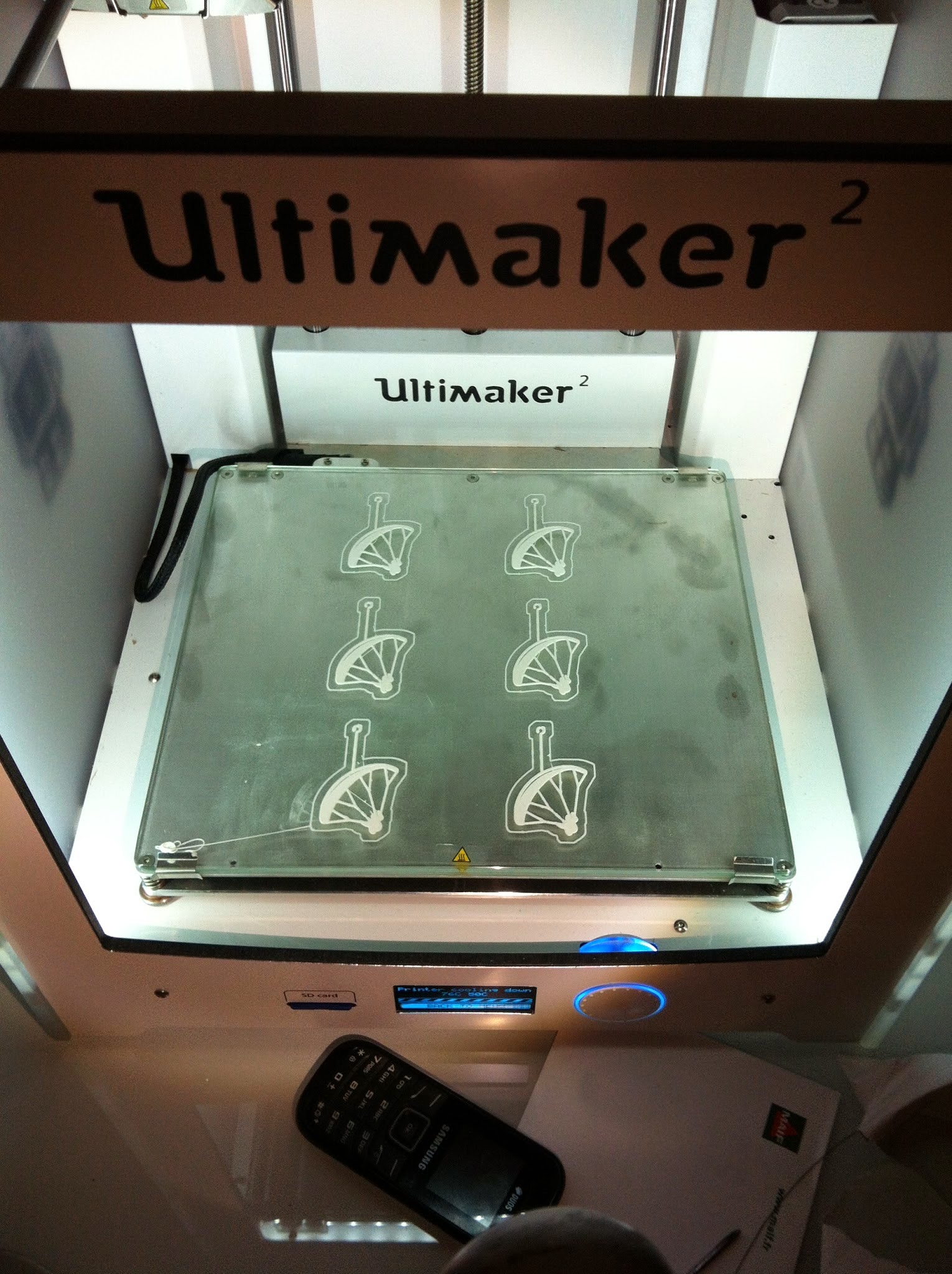

I again warmed up the 3D printer to try several types of propellers.

And it's going well 🙂

Now, the idea is to have the smallest and most resistant propeller possible, with enough force to start with small winds.

But I still had a little problem: You must not have a 3-blade propeller. Otherwise, serious problem. In light winds, it does not have the strength to lift the bottom blade:

Gling gling gling

And since last Sunday it was ugly, we stayed at home. But not to work on Pioupiou − because the weekend is sacred!

So, we thought it would be cool to be able to have a little ancestry at home, even if it doesn't fly.

So I played with the 3D printer again. This time to draw small paragliders:

And I installed them on the Christmas candle. Which suddenly gives The Christmas thermal ».

And since we thought it was too cute and I'm crazy, I sent the drawings to the factory, just to see.

And on Thursday they sent us the photo of the prototype:

As it looks cool, I validated. In 15 days I have 300 in the mailbox. Too easy !

So they are on sale http://meteo-parapente.com/noel

A+

4 thoughts on “ Fly to work »

Hello,

– The propeller must (should) turn below 10mk/h

– I vote for 1 or 3 at the level of the propeller.

Question for 3: is it a problem if the mass (the bearings) is stronger at the level of the propeller?

in short, in other words, mass of the bearings versus mass of the propeller and resistance of the axis.

Phil.

Hello,

I vote for the polymer bearings in the propeller. you have the possibility of reducing the diameter of the tree at the level of the bearings (just to reduce the friction torque to the max). on the other hand, the part of the shaft between the propeller and the body of the pioupiou can remain large.

I thought for a moment about polymer ball bearings:

http://www.igus.fr/wpck/4963/xiros_B180

but at the pollution level you gain nothing

your project is really cool! good luck for the future!!!

small question on the propeller: whatever it is must be balanced (its center of gravity at the level of the axis of rotation) so there should be no concern for gravity. Unless I'm wrong 🙂

@Romaric yes you are right.

Each propeller blade exerts a torque. let alpha be the angle of the first blade with the vertical, then we have alpha +120 degrees for the second blade, and alpha + 240 degrees for the third blade.

The torque is of each blade is proportional to the horizontal distance between the center of gravity of the blade and the axis of rotation. Let total torque = Cte x (sin(alpha)+sin(alpha+120)+sin(alpha+240)) = 0 whenever alpha:

for unbelievers, use this formula sin(x)+sin(x+120/180*3.1418)+sin(x+240/180*3.1418) on http://fr.numberempire.com/graphingcalculator.php