The little life of prototypes

Prototyping isn't that easy. In fact, it is often even a disaster.

When I made the very first Pioupious, in June 2014, I was very happy. I naively thought I had finished the project 🙂 But in the end...

When it smokes, it's not a good sign

And the first bug happened: the batteries were getting hot when I installed them. There was obviously a short in some cases with the battery connector touching the board. It was smoking.

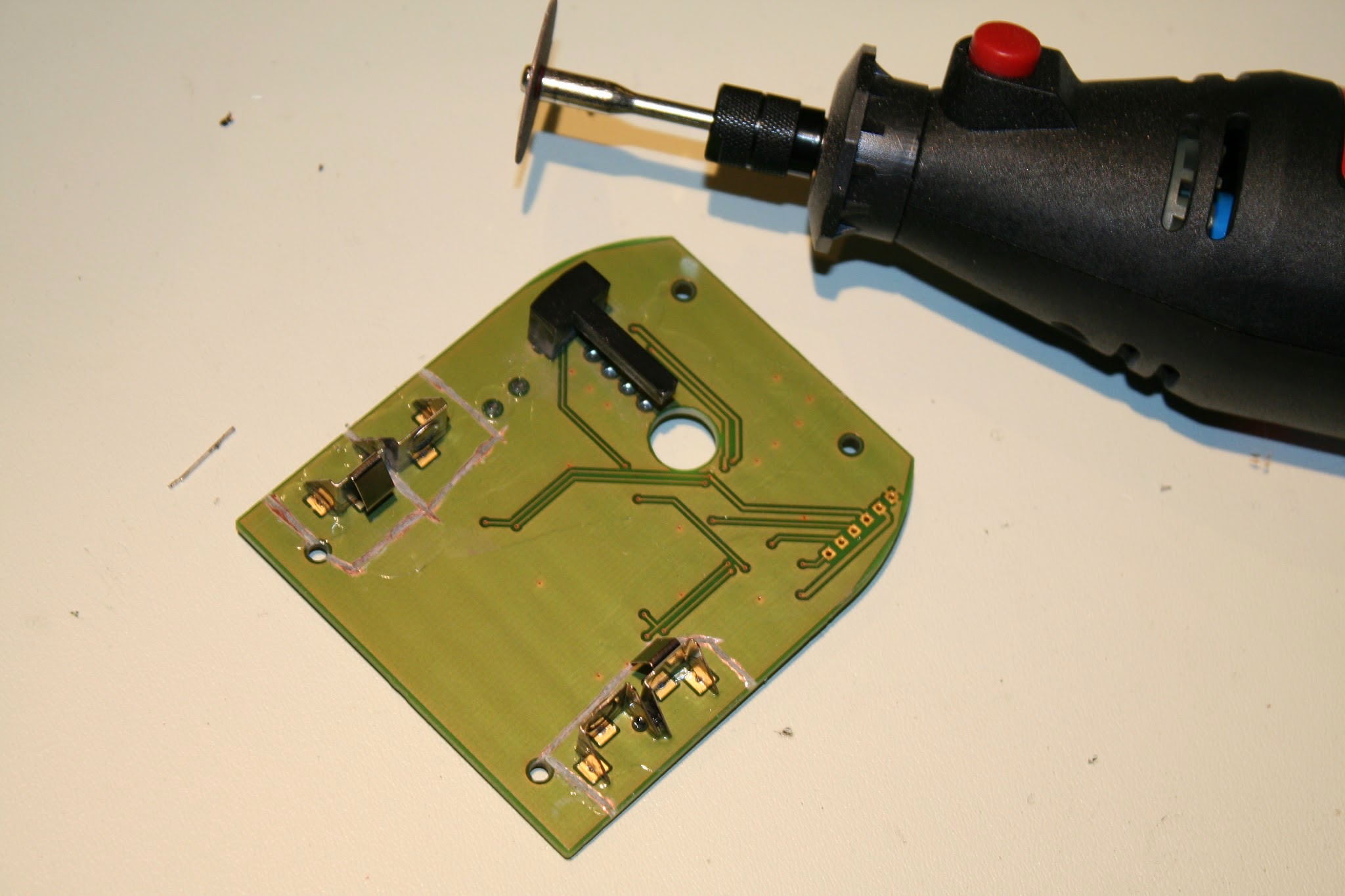

So, not even badly: I took my little Drémel, and I corrected the 30 prototypes by hand. ☑ Issue resolved

When it burns, it's not a good sign

After that, I delivered the prototypes. We have installed about 25 throughout France.

They worked well for about…a week! Yippee!

But after a week, a Pioupiou stopped broadcasting. Then another, then another.

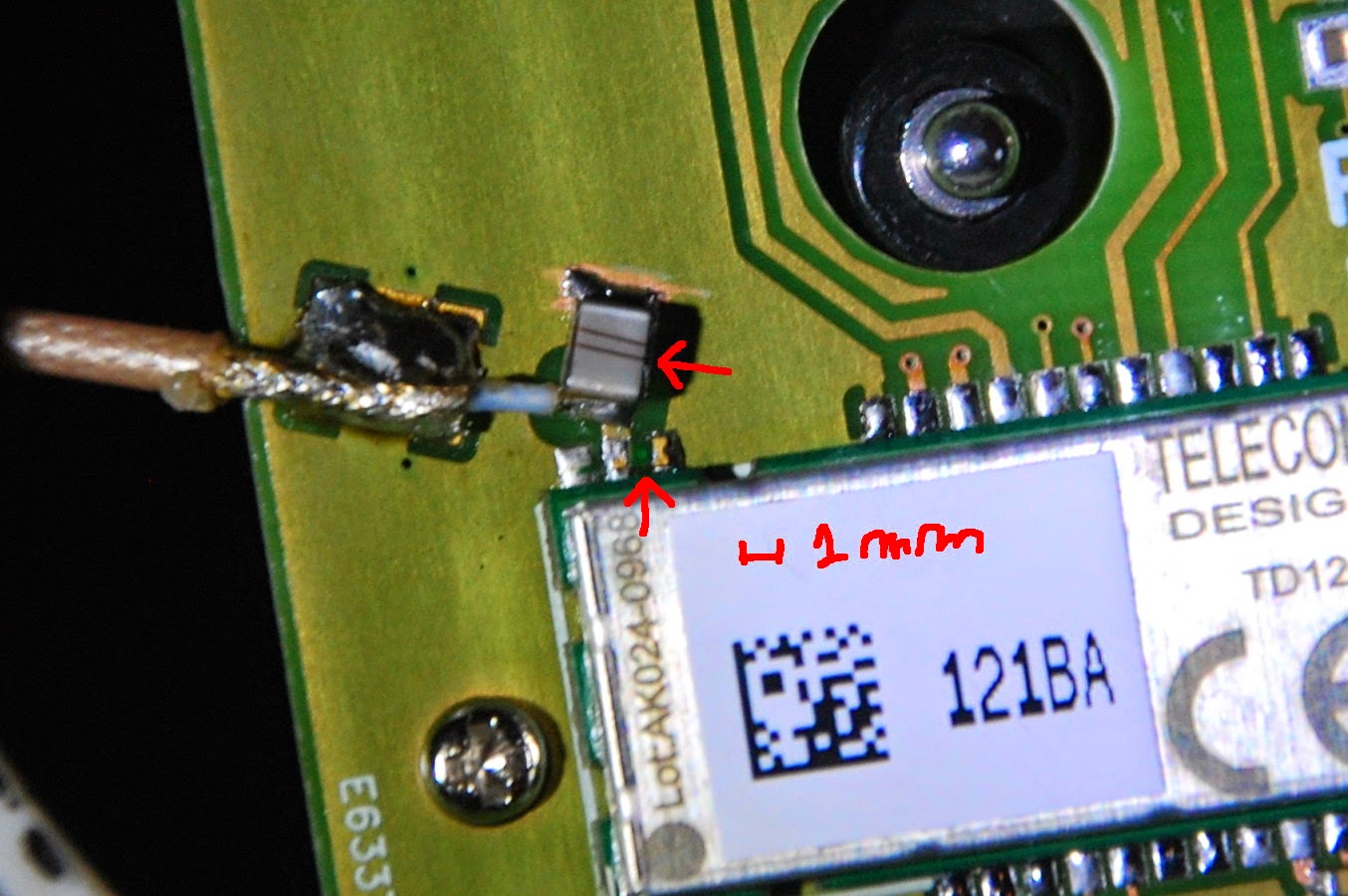

We racked our brains a bit, then we quickly understood: Pioupiou captured the static electricity of storms. It caused a surge in the antenna, which fried the transmitter.

No luck, it was summer − the stormy season. Half of the prototypes went through it...

Finally, we found the solution: two small components to add − 40 cents.

Since then, no more Pioupiou have burned out because of the storm. ☑

Problem solved

When it breaks, it's not a good sign

Finally, in mid-January, we started to try the prototypes of the " new » Pioupiou.

This time, the bug took a little longer to arrive. Finally, 2 weeks, what.

It gives that :

The propeller " proto 3D printed is not very well balanced. When it spins at high speed, it vibrates − a little too much.

I had underestimated the effort: the axes did not resist. They broke at the grooves for the elastic rings. Plus I had machined them by hand − that didn't help matters.

Brief. I have 3 out of 5 prototypes that no longer have a propeller. She flew away. Less practical for measuring the wind…

I am therefore studying how to solve this propeller axis problem. But don't worry: next week we'll have the solution 🙂

10 thoughts on “ The little life of prototypes »

Hello,

scale model propellers wouldn't work? comparable wind ranges, industrial therefore balanced and robust, not expensive

I am testing this

I don't want to be a bad language, but the 1st prototypes seemed to me more reliable once modified for the storm….

I had a lot of problems with breakage and mechanical links that wear out. So it is not possible to deploy hundreds of them. It's going to be too much after-sales service for me to manage. It is better to spend a little time developing a robust mechanic and that in addition we can improve. (which you couldn't do with the commercial anemo I was using)

Why not a horizontal propeller (cups) rather than a vertical one? Suddenly no more problem of gravity mentioned in the post "Fly to work" ... Anyway the pioupiou no longer has the original shape!

and ultrasound, ?

We don't see many propeller anemometers, to tell the truth I've never seen one. What is the reason for this and why are cup anemos preferred? what happens in icing conditions, how reliable is the reading of the wind when a layer of frost modifies the geometry of the propeller?

Propeller anemometers have established themselves as the standard in all ski resorts. I also have colleagues from the LGGE who install them for their measurement campaigns in Antarctica. It is much more robust than cup anemos.

This comment has been removed by the author.

Congratulations on your project, really nice!

Looking at your concern with thunderstorms… I wonder if you already had some kind of ESD cap on the prototype that we fried (wasn't enough?) or the antenna was directly connected to the chip without anything else . (I apologize for my bad French.)