Pay your mold!

We still have a few tweaks to make. But overall, we are very close to the finished product.

So I started ordering the parts that I'm sure won't change: Sigfox and GPS chips, batteries (which work from -60 to +85°C!) and lots of little odds and ends... take it a little in advance, because supplier deadlines are a little longer than at Amazon.

And in this series of pieces that will no longer change, there is notably THE HELICE. That alone is quite a story!

Chantilly or chestnut cream?

Me, I like waffles. It's super super good, and in addition it reminds me of my youth when we would eat waffles on Saturdays, in the castle park.

So, to make the waffles, you need a mold:

You need dough:

And above all, you need a lot of very fatty and sweet things:

Yum!

It's the same as making Pioupiou propellers. Except that the helices of Pioupiou, even with a lot of Nutella, I'm not sure it's very edible.

Short.

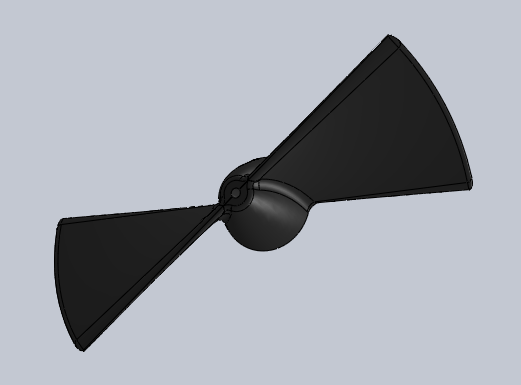

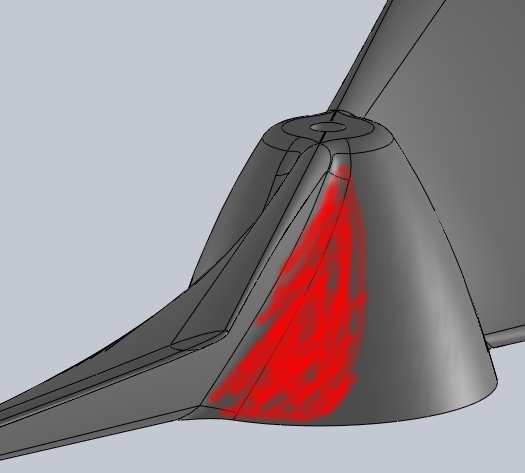

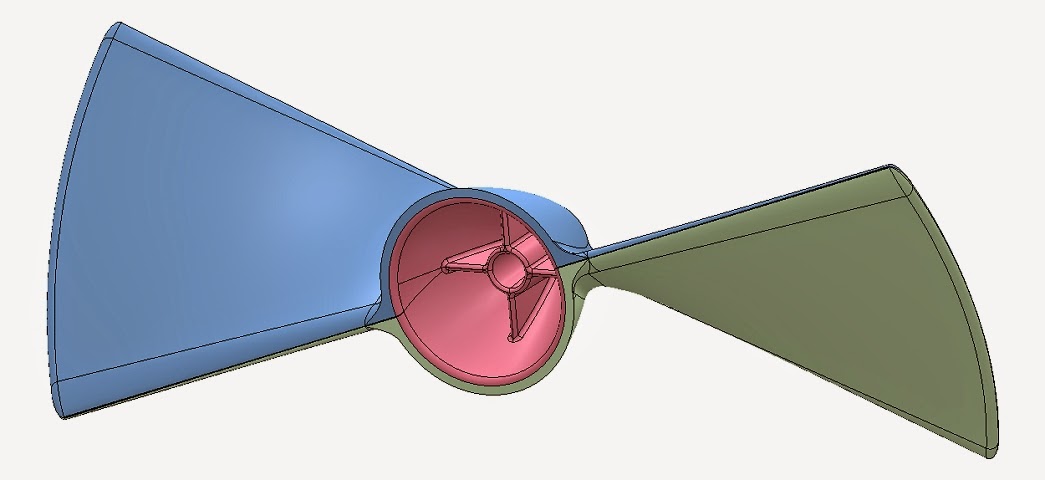

We want to make a waffle that looks like this:

And if she looks like that, it's no coincidence.

A cone, you will mold

The important thing is obviously the blades.

In theory, it's no more complicated than the waffle.

Except that obviously, we have a problem…

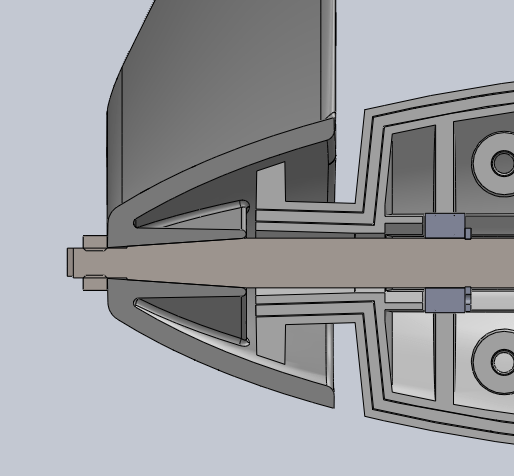

The center of the propeller should be cone-shaped. This is to ensure the tightness of the connection:

Except that with a cone-shaped hub, there's a part you can't mold. It is hidden between the blade of the propeller, above, and the base of the spinner below.

Of course, I'm not the only one having this problem.

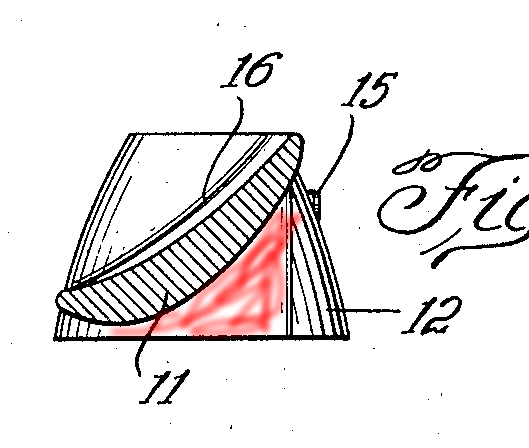

Un first solution consists of adding material to fill the "vacuum" under the blade:

But for us it doesn't work. Plastic molded parts must have the same thickness everywhere - otherwise there is a risk of deformation or holes. Here, it would be too thick.

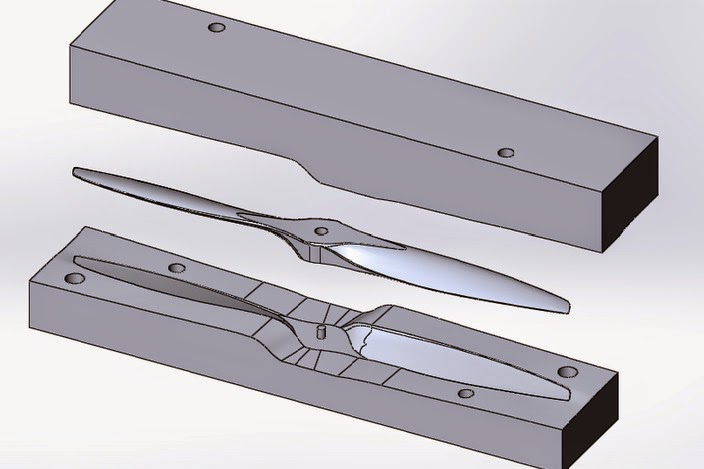

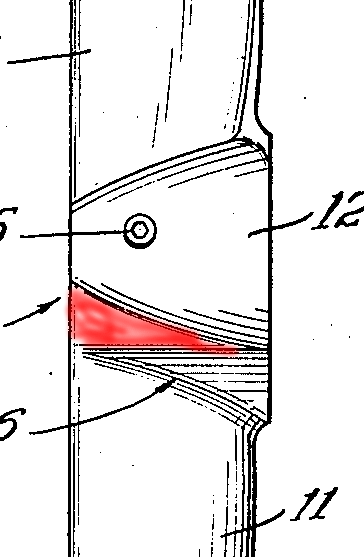

A second solution consists of working from the side, with a mold in several parts:

The problem is that it complicates the mold enormously − and as a result it costs too much…

Two blades, you will put

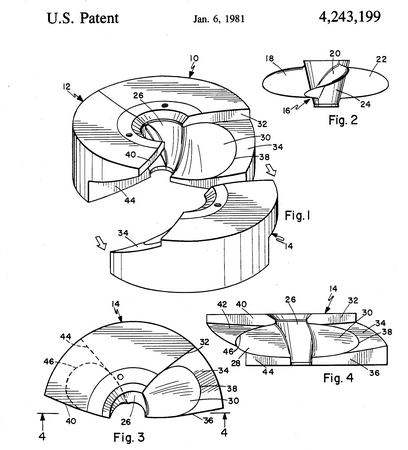

The solution I found is to put only two blades.

So, I can stick with something simple, with an improved waffle iron:

A shell up, a shell downstairs, and a drawer to make the inside of the cone.

Straight walls, you won't

There remains the problem of the axis hole.

In molding, you always need “remains”. Translation: the walls of the mold should be slightly inclined.

If the walls are too vertical, it rubs and our waffle may get stuck.

It bothers us, because suddenly we can't make a very cylindrical hole to pass the axis.

The classic method is to make a conical hole and then put a drill to it to dig the right shape. This is what is done for example for model aircraft propellers.

Except that not only does it require extra work, but it's also complicated to make the hole right in the middle. And if we miss, the propeller will no longer be well balanced.

Suddenly, I didn't bother my head: I made a conical axis which matches the shape of the propeller. In addition, it will ensure good centering. Kind of like a drill chuck.

Good dough, you will do

Finally, our waffle batter is called Bayblend T65 XF. It is a mixture of ABS and polycarbonate. Probably the same material as your phone case.

It's the best compromise I've found between strength, ease of molding, UV resistance and cost.

The propeller will be black. For UV resistance, but also to melt snow.

Let’s do it !

After too many hours of blabla, and as many 3D-printed tests, I took the plunge. And so I ………… started the manufacture of the propellers! Whooaaaaaa!

It's very scary. Even more than buying to buy a used car. Is this the right one? Is there no hidden defect? If we got the wrong car, we can always try to resell it. While to refourguer a failed mould, good luck...

Brief. It's the biggest and most uncertain expense I've made in my life. But hey, if you don't take any risks and stay safe in your bed, it's sure that nothing will happen.

Now all you have to do is cross your fingers. Verdict in 2 weeks!

6 thoughts on “ Pay your mold! »

Hi Nico,

Really FASCINATING, your approach! For about 1 month I have been consulting your blog regularly, often even, because I have always had a great admiration for those who innovate, take risks and show an unfailing determination.

And since I'm a technology and electronics enthusiast, it touches my heartstrings.

I dream, in the nearest possible future, of seeing Pioupious on take-offs from Quebec flight sites. Too bad the Sigfox network is not yet on the other side of the Atlantic… Do you have an idea of how we could make it work for us? I am afraid that not only is there not yet a network currently in place for the IOT but I read somewhere that it will be the 900 MHz band that will be allocated in Canada (and the USA). So in this event, it would make your current Sigfox module unusable here. This would therefore require a version for America different from that for Europe.

Come on! we all meet, the foigts so that your mold is the right one! GOOD LUCK!!!

The mold with the fries, that will do it!

well now that things are getting clearer, it might be time to update the photo (non-contractual) on the page where newcomers might want to order, them and them too?

Don't stress about delivering the PiouPiou on time, take your time to make us a device like we dream of, and if there are dissatisfied people, it's because they don't know what creativity is, passion and work.

on the first prototype the axle had farted, did you solve the problem?

It is all good. The axis is now 5 mm instead of 3, and the grooves are shallower.