Bon Pioupiou for 2015

I haven't given too much news in recent weeks. We'll put that down to Christmas, New Year, fatigue... All that, what.

In short, we are in 2015. Here we go again.

There is still tons of work to do, but we can say that the site has nevertheless progressed well.

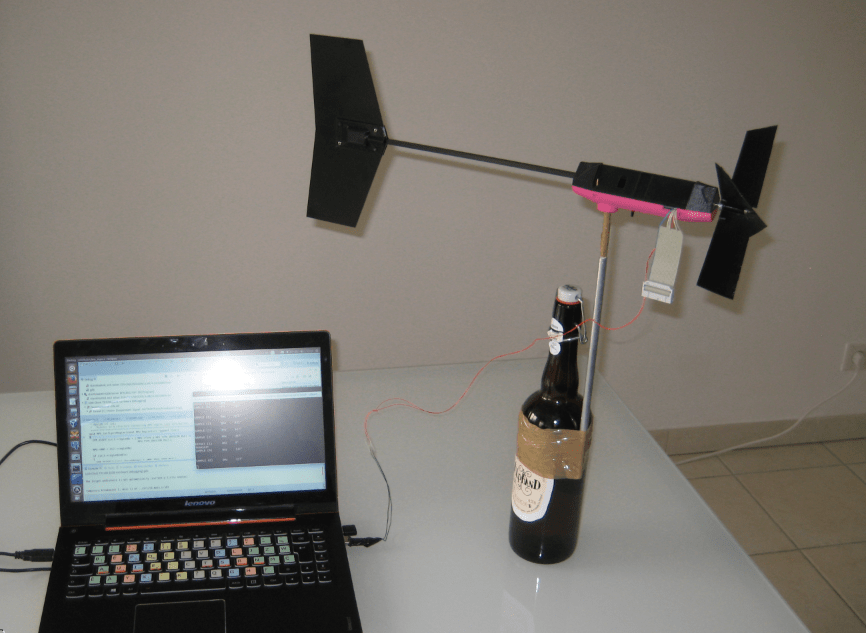

Good news: I finally have a working prototype of the new Pioupiou.

Well, actually for now it's still hooked up to my computer. But he will be able to take to the air tomorrow.

Finally. Before that, we had to spend a few hours there…

Plastic, It's Fantastic

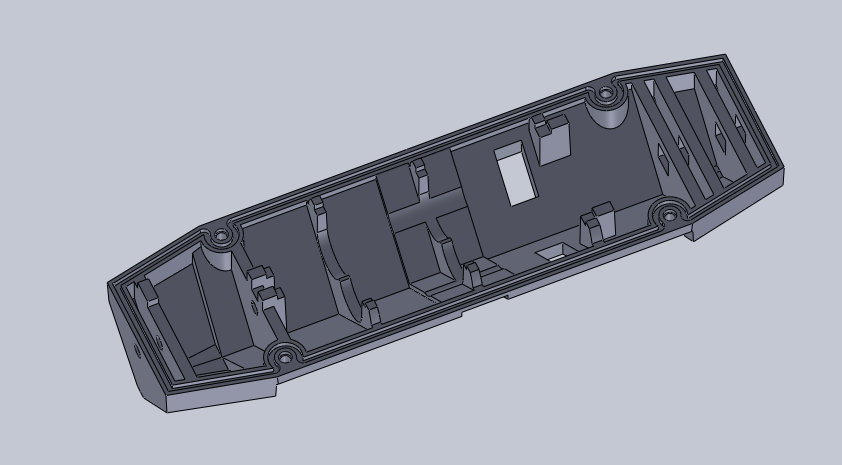

Already to draw the box:

It looks quite silly. But in reality, it's a real battle. There are lots of constraints to be able to make an easily injectable part: thickness which must be uniform, minimum inclination to allow demolding, and so on…

Beyond these constraints, there is the second important point: everything must fit together correctly. There, I admit that it took me a few tries and adjustments.

The good thing is that I almost finished my roll of plastic Rose for the 3D printer 🙂

It beep beep

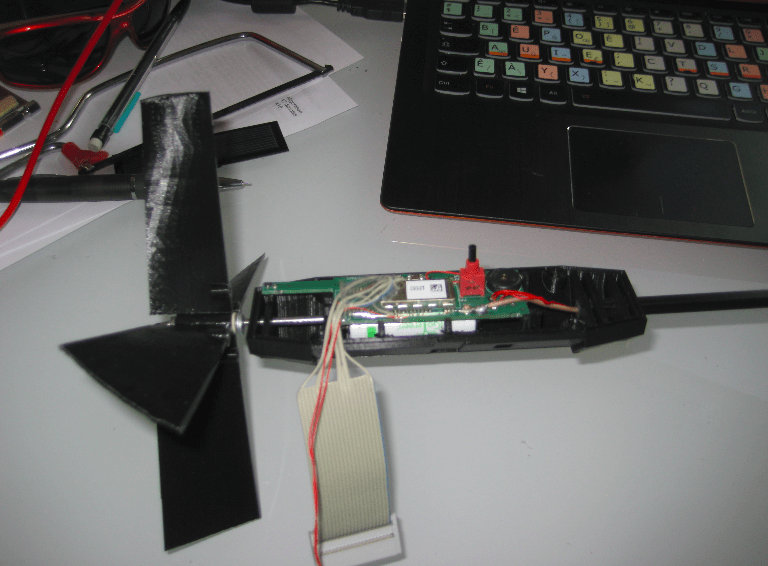

Finally, it works fine. The card, batteries, solar panels, and everything:

So I was able to take the opportunity to actually test the electronics.

There, no bad surprise (for the moment). A good dozen small adjustments to make, but nothing serious. THE " worst is the beep that sounds not loud enough when the on/off button is pressed. But we will find a solution.

And even, good news: the magnets placed on the propeller do not disturb the compass. (Well, actually I had already done the theoretical calculation. But it's always good to have experimental confirmation). So that's great. Pioupiou will always give us the correct direction of the wind, without having to check that it is well aligned with the North.

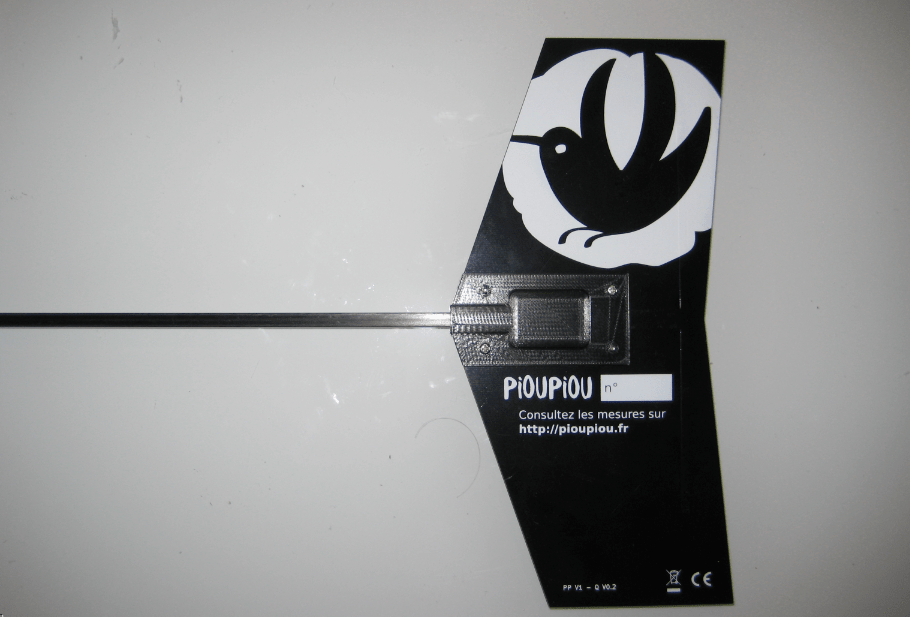

The beautiful tail

In the previous episode, I had started the development of the antenna. So to test, I had new cards made for the queue.

That's when I realized that " oh shit! it's Christmas ". And suddenly, it was not easy to find a factory that could order the cards on December 23 to receive them on January 2. But I found it, and the result is pretty cool!

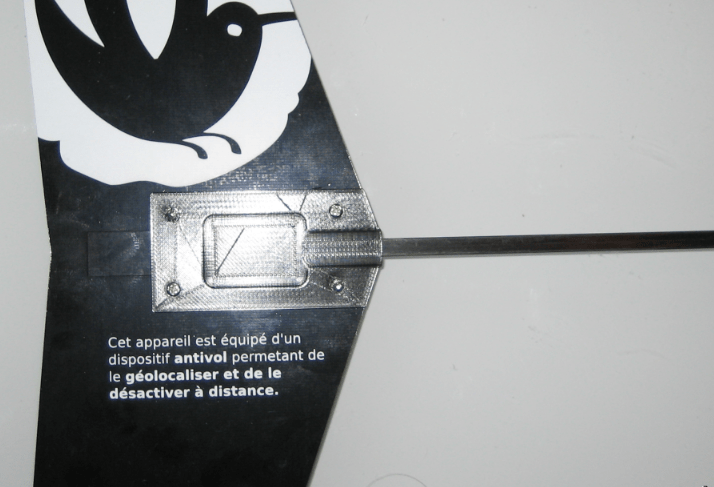

So here is Pioupiou's tail, almost final version:

And I took advantage of the screen printing to put a text that scares the bad guys:

Well, on the other hand I have absolutely no idea how these drawings will hold up to UV. Basically, these are paints intended for making markings on electronic cards, not for Pioupious exposed in direct sunlight. No way to do otherwise for the moment. You have to make compromises… We will see in the long run what happens.

But personally, I think it's a good solution. Because in addition to being ultra easy and reliable to manufacture, it is also super light:

Here, the complete cue set weighs 35 grams, while still being quite strong. (carbon rod + fiberglass card)

Technical specifications

As the project progresses, I am bombarded with emails. And in general, it's often the same questions.

Especially : " What are the technical characteristics of the beacon? " or " Do you have technical documentation? »

If there is one thing to understand about this project, it is that we are not in a classic pattern. Usually a manufacturer works " secretly to develop a product and then market it. It is therefore easy for him to give specifications, since the product already exists.

Here, we are still at the design and experimentation stage. I made the choice to do it publicly, because I think it's more interesting for all of us.

But suddenly, the product evolves every day. It is far too early for me to commit to specifications or a technical solution to use or not. I can very well completely change the design tomorrow, if I find a great idea that will make a more solid Pioupiou.

Since I am in a research and development phase, it is completely impossible for me to know in advance what will happen. That's why we say " research ". If I'm looking, it's because I haven't found yet...

Today, I sell Pioupiou as being " a small, affordable device designed for windsurfers and paragliders who want to know live how the wind is at their spot ". For now, that's the features.

I've been working on the subject for a year, well over 35 hours a week, without pay and with an extremely limited budget. I'm doing my best, because the subject is really close to my heart, and I'm sure we'll have a good result.

For those for whom these characteristics are enough, it's perfect. You can Order a Pioupiou right now, and suddenly allow me to develop this project without having to take out a loan from the bank or seek shareholders.

For those for whom these characteristics are not enough, no problem. You are under no obligation to order today. You can wait a few months until the release " opening " of the product. At that time, you will have all the detailed technical specifications.

In any case, remember that ordering a Pioupiou is not like buying an iPad on Amazon.

Question existentielle : to mold or to print ?

After this long speech, back to practical questions to illustrate the kind of choice I have to make.

There will be 5 plastic parts on the current Pioupiou: the propeller, the upper and lower hulls, and the two (identical) parts that make the connection between the stem and the tail. The idea for now is to do this by injection molding. Like most plastic things we have around the house.

As it stands, it should cost me between €10 and €15 to make the molds. (It's really cheap, actually). It's not a problem, it was what was planned, and I will probably do it.

The idea is that all the same, it's a lot of money. Above all, it's a lot of money to make molds that we may want to change after the first series, because we will have found lots of little details to improve. And once you've slammed €15 into the moulds, you don't necessarily want to change the design...

So, by dint of making my prototypes with the 3D printer, I really ask myself the question… Should I mold or print?

Knowing that 3D printing is still very slow: ~ 24 hours for all the parts of a Pioupiou...

Knowing that it will be less clean than injection. But that all the same, what I've seen so far seems to me to be quite robust...

Knowing that Pioupiou is a product that will be installed in nature, at the top of a pole and that suddenly it is perhaps not so serious if the external appearance is not perfect...

Knowing that printing and electricity costs remain reasonable.

Knowing that making printable parts is much less stressful than making moldable parts.

Brief. If I spend €15 on 000D printers rather than molds, that gives me a production capacity of at least 3 pioupious/month. Except that there, the advantage is that I can improve the design when I want and even make other products...

On these volumes, the question really arises. Obviously, if afterwards we sell thousands of Pioupious, we will make moulds. But now I'm not 100% convinced. What do you think ?

(For the propeller, it will be molded in any case. We have no choice if we want a good calibration).

Well, apart from all that, I'm going to try to make several prototypes next week. That way we'll be able to take advantage of the winter to put this Pioupiou to the test.

bye

25 thoughts on “ Bon Pioupiou for 2015 »

the impression, the external appearance is not essential. On the other hand, under-treating the printing seems preferable to me.

Well done Comtin

Great I share Thierry's idea... if you want to test the strong wind I'm in the middle of the mistral zone 😉

This comment has been removed by the author.

great your pioupiou beacon, I voted for the purchase of a beacon for our flying club and the order will follow before January 18th. Kudos to the inventor.

I don't know what type of molds you're talking about, but there are plenty of possible versions. In general, to make small series, aluminum molds are sufficient, quick to machine and therefore relatively inexpensive, but it may already be your 15k€. Do you have a designer of injected plastic parts in your knowledge, it would be in your interest to give you all the experience necessary to make moldable parts at low cost? I don't know enough about plastic printing to have a relevant opinion on the lifespan and pay attention to the appearance, to generate confidence in a product, the aesthetic aspect is essential….and you want this to develop , so don't neglect the aspect. :). I have some acquaintances in the world of plastic injection, do you want me to ask them to take a look at the piou piou?

In fact, I've already managed to lower the costs to the max, with aluminum moulds, etc. It costs me ~ 3000 € per mould. Which is little. The question was above all whether it is more strategic to invest in molds or in a more versatile production tool.

plettil is right, the aesthetic aspect to develop the confidence of people who have not followed the project closely. But as usual you found an effective and cheap solution

GO AHEAD …

Hello,

GOOD! In my opinion, part of the investment of the molds is in their structure which can be reused in the event of modification of the imprints. So you don't put 3k€ in the trash. The idea of a hybrid version in the comments may be an opportunity.

From a strategic point of view, for your customers, it is also relevant to have little modification during the evolutions... if only to homogenize a PiouPiou aviary and ensure repairs... with a homogeneity of the spare parts.

Good luck!

Just congratulations and Happy New Year...

You thought of a hybrid solution: molded outer shell and printed inner supports. So you can easily upgrade at least the interior. Otherwise subcontracting also seems more profitable to me than ordering lots of printers.

Stupid question but which has its interest here: how many are you planning to sell, on this model, and how many in total? There are about 600 paragliding sites in France, say 1000 pieces for sale with clubs, and the addition of other points or abroad, the purchase of a mold which will only be amortized in 1000 or 1500 parts does not necessarily seem to me to be the right approach. But buying a new printer for a shorter time may not be the right solution either. A design freeze, to move more quietly from one version to another is also to be considered, to have time to produce, and to ensure availability...

There are a few windsurfers and kite surfers who may be interested, plus port authorities and other nautical clubs, not to mention all the wind aficionados who buy weather stations...

Best wishes to you all.

The 3D printer first strategy doesn't look quite good.

The possible evolutions are the major justification.

The propeller which is the weak point in terms of life must be taken care of, which seems to be the case.

This project is worth to be led to its success, good luck.

Cdlt,

Yanik

Great project! You sell dreams …

I will choose 3D printing in small quantities because at the beginning the orders will be low and the adaptability better according to the RD. Also a versatility, when inventions germinate in the head you have to be able to grow them.

Given the progress of 3D printers, I will not start buying an entire fleet; this allows you to adapt according to demand; better flexibility...

I don't know anything about durability, but that's an important point.

A paraglider who dreams of multiple data (wind pressures) to see new algorithms emerge.

Long live 2015 and Bon PiouPiou

I installed the prototype in Corsica, we are going to test it now the maximum wind threshold is a little weak for my region.

small problem with the wind vane I installed it yesterday morning it always tells me NNW either there is not enough wind to turn the weather vane or the Pb is elsewhere http://pioupiou.fr/32

I had trouble soldering the compass chip (3x3mm) by hand. At first, it didn't last...

yesterday I had SOUTH WEST yesterday evening NORTHEAST this morning again NORTHEAST we should have more wind today we will see what it will give

for the weather vane at my level I can not do anything?

I looked at the data, and indeed there is a problem with this weather vane. The problem is that it's such a small component that it's nearly impossible to solder it properly by hand without the proper technique and equipment. So for now we have to wait. I will send you a next version prototype as soon as possible.

ok would it be possible for you to increase the wind speed threshold to 80 or even 90 knots, a big Libecciu is expected by this weekend we will see if the first prototype will resist

In fact, the wind speed is encoded on 7 bits, i.e. 2^7 = 127 possible values = from 0 to 127 km/h.

It's programmed in the Pioupiou's electronics. There is no possibility to change it remotely.

Then we might be able to better optimize the protocol. For example, say that from 100 km/h we count 2 by 2. That then gives us a maximum speed of 154 km/h, or 83 knots.

Eventually I have 8 bits left available in Sigfox messages. With that, I can either: double the precision of the wind (256 possible values instead of 127), or double/triple the precision of the wind vane. (32 or 64 possible values instead of 16 currently)

first big Libeccio last night the pioupiou is installed in the valley the recorded values are low compared to various data around good I do not have a history over 2 rolling hours I did not exceed 30 km / h for the gusts, in comparison port trade 145 km / h at 7 am, the pioupiou is located in a valley oriented W / E the prevailing wind is currently sw ca can explain the low speed of Pioupiou !!

good the first prototype did not hold the first Libeccio the axis of the anemo broke

That's a great project! I tell everyone that you can make wind turbines with almost anything, even recycled/reclaimed materials. In addition, wind power is so much more profitable than solar panels which also have a shorter lifespan… Bravo for your initiative and good continuity!