Tutututututututututututututututututututututututututututututututututututututututututututututututututututututututututututututututuuuuu

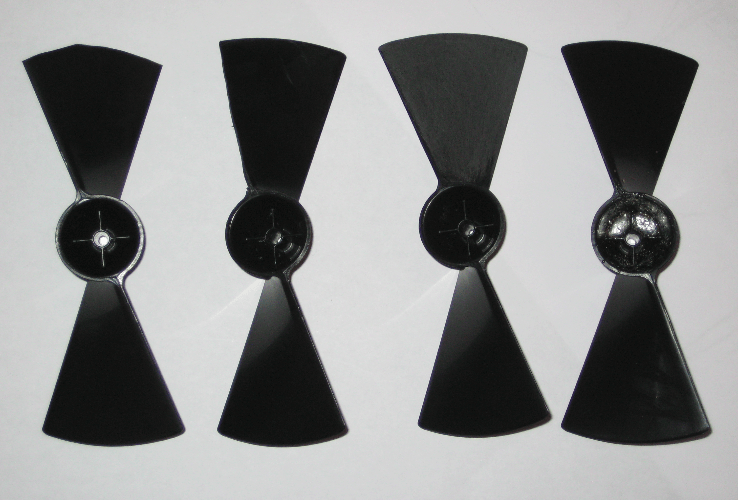

I received the propellers 🙂

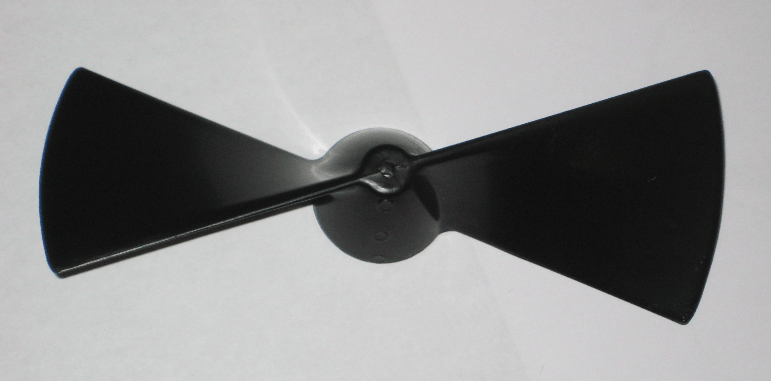

Look how beautiful they are:

Not only are they all shiny, but they also look mega-strong. I couldn't even break them.

Good job for my very first plastic injection parts. They fit together exactly as they should.

...

...

...

...

Well no, actually

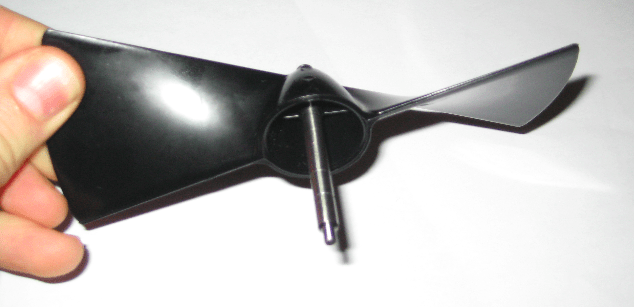

After installing the propeller on Pioupiou, I had a little doubt.

« Why is this blade always leaning down? It's supposed to be roughly balanced normally. »

I tried with another propeller, then another one, then another one… God damn it! They all lean to the same side.

So I said to myself that it was surely not too serious, and that we could fix it by delicately filing the end of the too heavy blade. I finished with big scissors. The propeller had to be planed by a good half centimeter so that it wanted to be balanced. Houston, we have a problem.

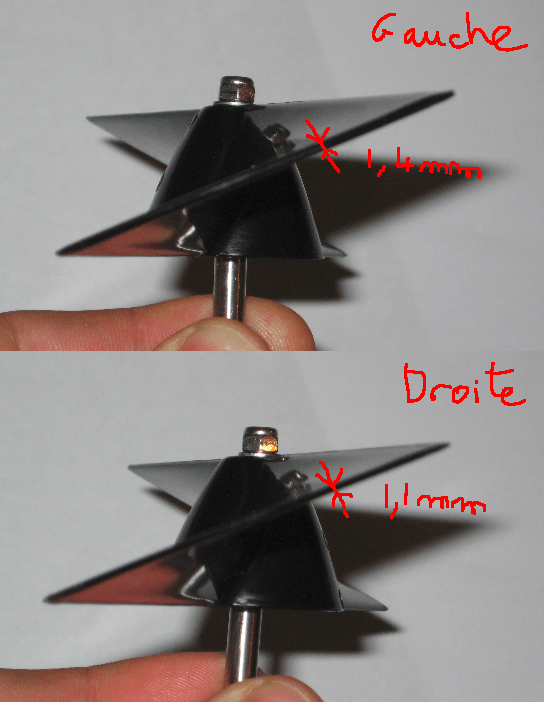

Finally, the problem was identified: the left blade is much thicker than the right blade.

Suddenly, it's heavier, and blablabla it makes everything screw up.

There, I said to myself that all the same, it was really a stupid mistake. So, I immediately checked my 3D file which, to my surprise, was correct. The problem therefore comes from the molding.

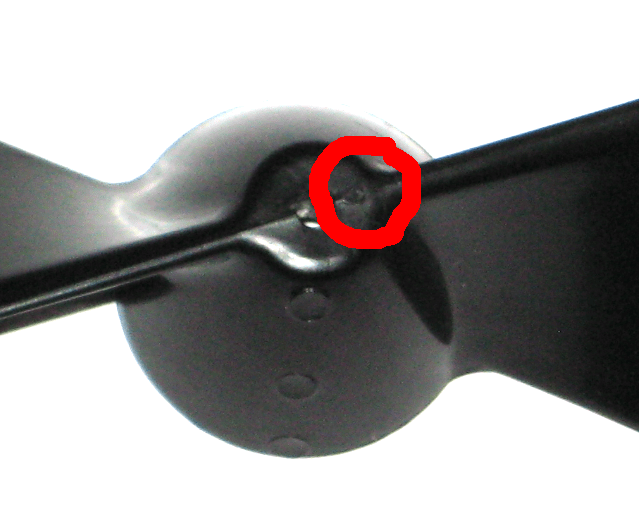

The plastic injection point is located at the start of one of the two blades. And as if by chance, it is this blade that is the thickest. I imagine that the bug is there: the plastic has less distance to travel on this side, it cools less quickly, so it fills the mold better − or I don't know what. In short, would it have been necessary to have a symmetrical injection point?

I'm disappointed. Kind of like a Christmas with lousy presents. " But mom, I wanted a drone, not pants! »

I tried a lot of solutions - each uglier than the other - to try to balance this failed propeller. Scissors, sandpaper, and even pewter counterweights.

Brief. Garbage can.

Ultimately, can it be recycled into a bow tie?

So I asked Father Christmas at the factory. He goes to see with his engineering elves to find a solution.

With luck, it will suffice to modify the injection parameters a little (temperature, speed, etc.). With less luck, we will still have to line up a few thousand euros to modify the mold.

Electronics

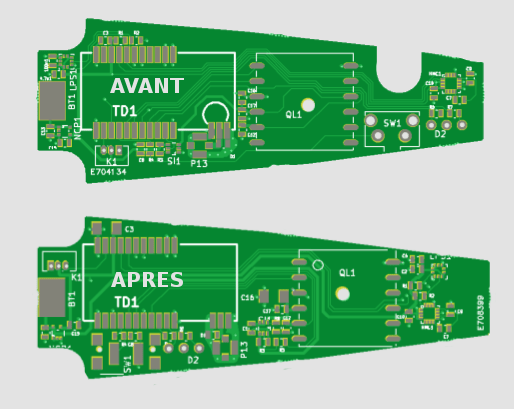

To console myself, I made changes to the electronics.

The scheme is basically the same. I improved the power supply part a bit, and I changed the layout of the components on the board. The button " was too close to the GPS antenna. It disturbed the reception.

The new cards are being produced. I'm testing this next week.

SiO

It seems that at the moment it is the great fashion for " connected objects ».

Brief. There is a connected objects fair in Lyon on April 7-8. http://www.sido-event.com/

I'll be there on Tuesday to present Pioupiou and advertise for Sigfox and Telecom Design, on the AVNET stand.

4 thoughts on “ Tutututututututututututututututututututututututututututututututututututututututututututututututututututututututututututututututuuuuu »

Hello

I know it's easy to make a comment afterwards, but it seems to me that "the factory is responsible for the bad filling". So we had to redo a series with the right time and temperature.

Well, it's always like that when we do things there are delays. COURAGE

It was too good to be true ��

Rob

The mold plant or machine shop that made the mold? I hope you in any case that the error comes from the richest who has the financial means to correct it :-) A difference of 0.3mm on the thickness is a lot and it would have taken almost a miracle for it to be correctable with a few strokes of the file… And putting a counterweight on the other side would surely modify the aerodynamics. Welcome to the world of cascading problems :-) Come on! GOOD COURAGE, you will get there with your ironclad determination!

negotiates with the supplier if the order specs were correct, it is up to the manufacturer to supply the exact parts