May 8 news

Here are the news from last week. Boo, not well, late.

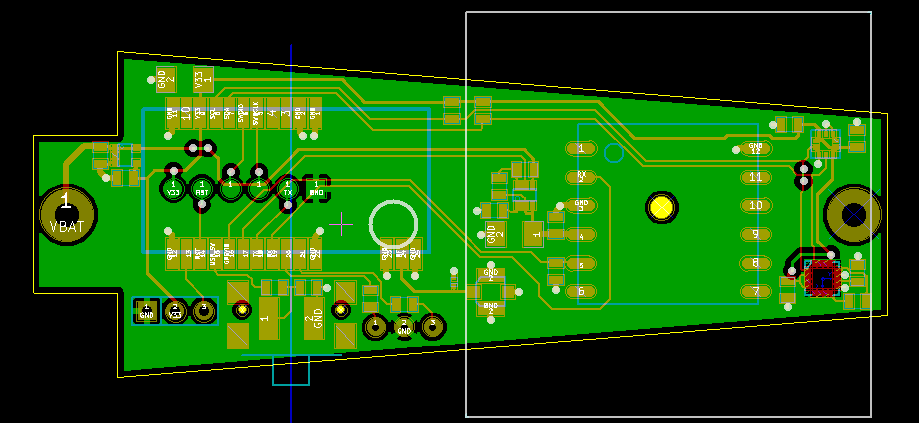

I spent all of May 8 (holiday) at an electronics consultant, to fine-tune the card one last time.

So, when I came home in the evening, I got kidnapped for the weekend − away from the internet. So this morning, it was panic:

The good news is that the electronic part is now complete. I have a few last tests to do, and I'm starting the production of 500 cards next week.

The less good news is that there are only 24 hours a day. I wish there were more − but it doesn't work that way. So yes, sometimes I have trouble finding 2 hours on weekends to write this blog. The impatient will survive until Monday.

We zap.

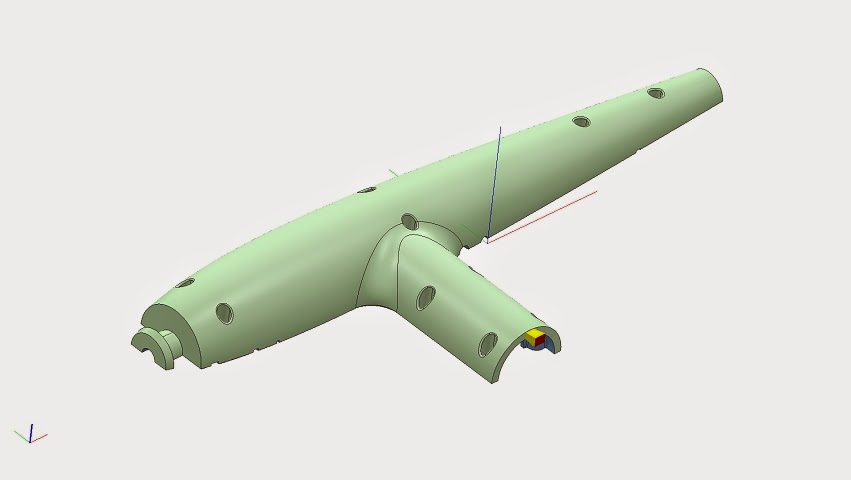

The famous propellers!!!

I received the shipping notice = I should receive the new parts within a week.

The first ones were unsuccessful. I sent them back.

A priori, they had to redo the mold 3 times before having a correct result. Not that easy as a piece...

So I'm looking forward to the package.

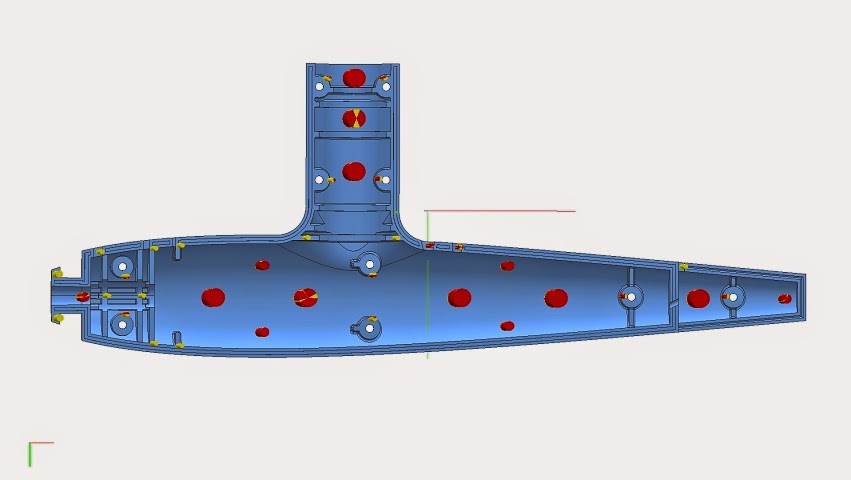

The fuselage

As long as we're in the plastic business… Hull manufacturing is on course.

The engineers have determined the injection point = where the plastic will be introduced.

They also placed the ejectors = the rods that help the part to come out.

I think they must now be making the mold. We should have the parts by the end of the month.

And then the other stuff

But what takes the most time is above all all the small accessory parts.

There's the silly stuff: Where do you buy self-tapping screws to screw into plastic?

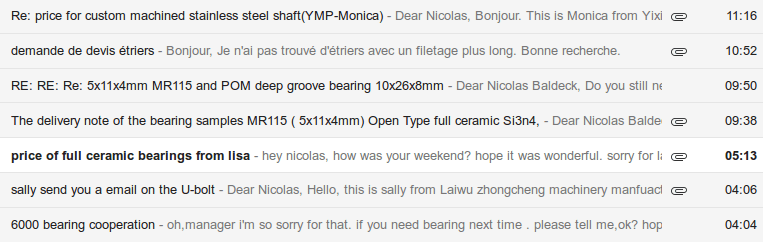

There are the rare things: Where do you buy ceramic bearings?

And then there are the things that are ultimately not so obvious: Where do you find U-shaped screws, the right size and which are resistant to seawater?

Short.

Send and receive lots of emails...

Make drawings...

Ask and test lots of samples…

Trying to guess which suppliers are going to be reliable…

You understood, there was plenty to occupy the last two weeks.

9 thoughts on “ May 8 news »

There are also silent patients who admire so much determination in the face of such a project.

Bon courage, sylvain

This comment has been deleted by a blog administrator.

The administrator no longer has a sense of humor?

Do not confuse private life and work

The realization of the propeller mold and its result seemed doubtful to me, but then the realization of the body and the location of the ejectors makes me think of a Chinese realization of today! 20 years ago we designed molds like that today we do better, at least in my box!

I stop denigrating because I am also impatiently awaiting my pioupiou.

A Jura plastics specialist

The company I work with is a leader in its field, namely easy plastic injection for prototyping and small series. I imagine that we can indeed have better studied molds, but probably not at the same price, nor with the same deadlines.

We can probably do more high-tech when we sell hundreds of thousands of Pioupious.

Hello,

Small technical help: you need self-drilling screws (and not self-tapping screws) to screw directly into plastic screw barrels.

Good luck

Yes. I got the term wrong. That's what I'm talking about.

Ok, parfait. Good luck