Too good!

I feel good… La la la la la la la…

I received the propellers… La lala lala lala…

They are too good… La lala lala lala…

In addition they turn well… La lala lala lala…

They are good… Are good… La lala laaaaaaa…………

...

...

...

...

...

You will have understood - this time, it's the right one!

In the end, I think we got lucky with the first propellers failed. The manufacturer had to put pressure on itself. They redid the mold three times. And now we have a spinning propeller.

Tested at 90km/h. Almost no vibration. Perfect balance. In short - it's won. It's really fun, because it was probably the most important and complex piece.

Side effects

By the way, I received the samples for the ceramic bearings.

|

| One classic bearing and two ceramic |

Result: no more friction. It runs incredibly well. Nothing to do with a classic bearing.

They are a bit noisy. But that's normal for ceramic bearings.

And so, once you couple those great bearings to the well-balanced propeller, the result is tip-top. The slightest breath, and it begins to spin. It is even much more sensitive than during my first tests. So Pioupiou won't be afraid of light winds.

Bearings: ☑ validated. Ordered 1000. Delivery in two weeks.

And how do we attach it?

You often ask me what support to provide for Pioupiou. So here is the final answer.

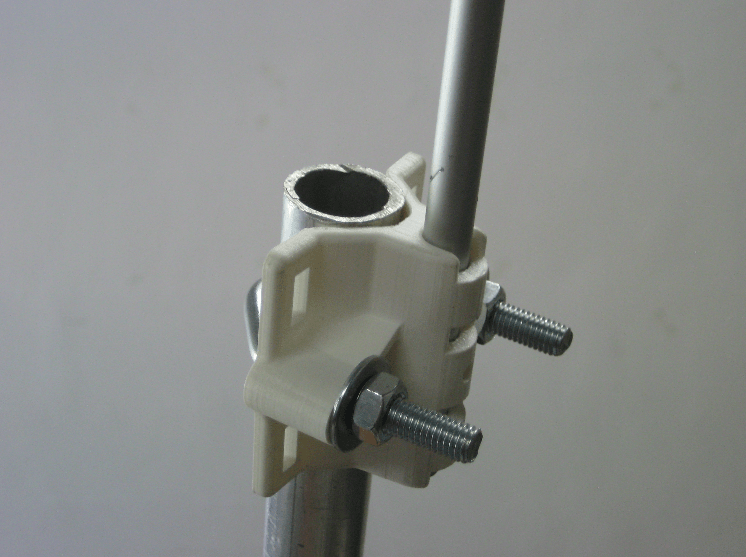

I made a plastic connecting piece, allowing Pioupiou to be attached to any flat or cylindrical surface.

The preferred method is that of the screw collar, compatible with masts from 20 to 45mm in diameter:

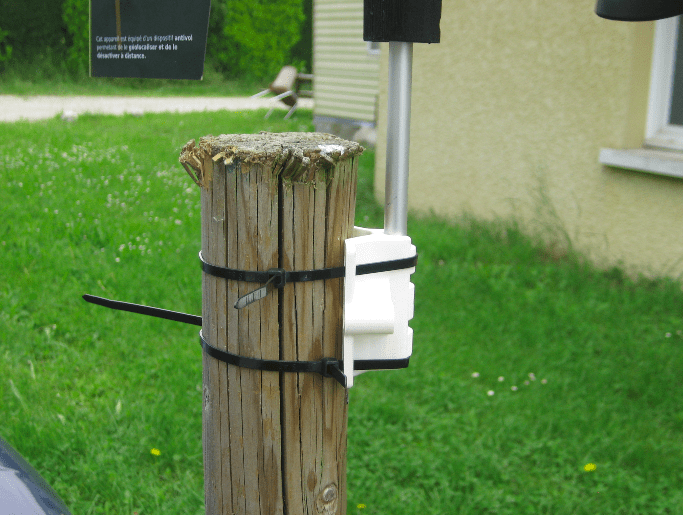

If you want a more ephemeral installation, or if the diameter of the mast is too large, you can use plastic collars:

Personally, I find that you can make an excellent support with an old windsurf mast. You can find it cheap on the right corner or in the neighbor's attic. The most common are 4m60, but there are also 4m90. The more neon, the better 🙂

Directive

We now come to the moment that makes us cry. The moment everyone dreads. Yes − of course I am talking about certification!

The villain is called 1999/5/CE − or "R&TTE" for short. This is a European directive setting a certain number of rules to be respected in order to be able to apply the CE logo on Pioupiou. Without that, no right to sell there in the union.

For us, this directive is transposed in the form of several standards. On the program: electrical safety and electromagnetic pollution.

So I started the painful work: writing the technical blabber and beginning of the tests. Fortunately, I have good connections − that helps.

By the way, I think we're going to have a lot of problems in the years to come. The current system is outdated. Before, only big companies could get into hardware – so it was easy to send €15 to a lab to outsource compliance. But times have changed. With internet, Arduino, and 000D printing, anyone can now launch their product with little means. The result is that we will have products on the market that are less safe than Chinese products. Imagine: just to have access to the texts of the standards, you have to pay more than 3 €. What amateur will do that? And obviously, no way to "share". AFNOR kindly reminds us of this.

I will have to do an article on the subject, one day when I have some time.

And the rest

I have ordered almost all the parts needed. All I need are the electronic boards and the axles.

For the cards, I expect to confirm the final design next week.

For the axes, I asked for quotes from several Haute-Savoie companies. And yes, it's not just Reblochon. It is also the capital of bar turning.

In the process, I planned the Sigfox certification. I'm sending them a copy as soon as I get the real plastic bodies.

In short, the work is progressing… I will soon even be able to tackle the software part.

Meanwhile, the boxes continue to pile up in the office. And there's always a lot of weird stuff inside:

|

| is it radioactive? |

But what scares me the most is the stock of screws:

Because that means screwing it all up!

15 thoughts on “ Too good! »

Congratulations and courage for the future, if we were in the same department, you would have a guaranteed helping hand.

What a peach this Nicolas!

What an adventure this Pioupiou … you are approaching the goal … bravo !!!

Bert

I join "Italian and the Hacker" in congratulating! What a pleasure to read you! I can't wait for my bird! This week I watched a distressing report on the storm chasers… and I thought I saw a Pioupiou on one of their "tanks", you are already plagiarized! 😀

Hello,

I also saw this excellent report. It was actually a Young brand anemometer, very common in the weather world, see here: http://www.atmos-meteo.com/fr/produit/anemometre-girouette-jr

Good luck to Nico for the home stretch.

Effectively! thank you for the info on the Young brand, it's very similar, by the account the report that I saw looked more like reality tv in the relationship between the protagonists and that's what displeased me, d 'as much as by filming and risking despite their gear to make you suck, you don't learn when something...

Hello,

It's like promoting a new successful film, we distil info but not too much, we create a lack, a desire,...

Even if I am VERY impatient to receive mine for my paramotor site, your professionalism allows me to wait.

Don't forget to fill in this blog because as for the S..F (train) it is often understandable to be late but the lack of information is unbearable. I know time to write is not time to solder.

I think that for the rise in growth of the project, it would be necessary to open the code and the API quickly so that a community of developers becomes immersed in the project.

As Gadafi said, the pleasure is in the tent...

Good it is very bad, but in the meantime Pioupiou it furnishes.

Hello, can you tell me where you got your bearing samples.

Thank you in advance

Hello, do you have an idea of the delivery date of the 1st Pioupiou? We are all very impatient 🙂

counting by pioupiou:

1h assembly (well done)

30 minutes of adjustments, software installation

1 day minimum test

10 minutes of mise en colis

i.e. 1h40/pioupiou ……by working, 6 pioupiou per day

500 pioupious ordered….

the first steps before the end of June 2015 …the last …..September October if all goes well, no failure, massive return ….

But that's just my objective opinion...

And for those who had pre-ordered it to receive it in October 2014, would it be possible to deliver them in priority? 🙂

I find it borderline rude to want to calculate the assembly and preparation time of the Pioupious without having any information on the operating mode.

Honestly what… To be objective, you need to have a minimum of elements.

Obviously not, it does not take 1h40 by Pioupiou. Not only is the assembly very simplified, but it's also 2015: that means automation and subcontractors. You can imagine that it's not me who's going to solder the components by hand.

Awesome !

SIGFOX for the Swiss plateau (clear place) could it work?

If with luck you are not too far from the border…

You can try the coverage preview on this page: http://pioupiou.fr/couverture